Bomag – BMP 8500

Bomag – BMP 8500

BRIEF

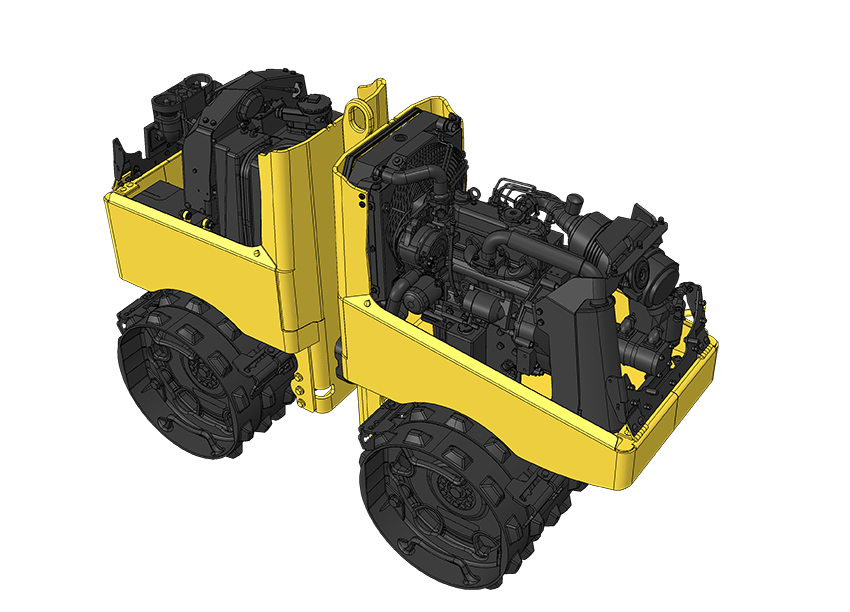

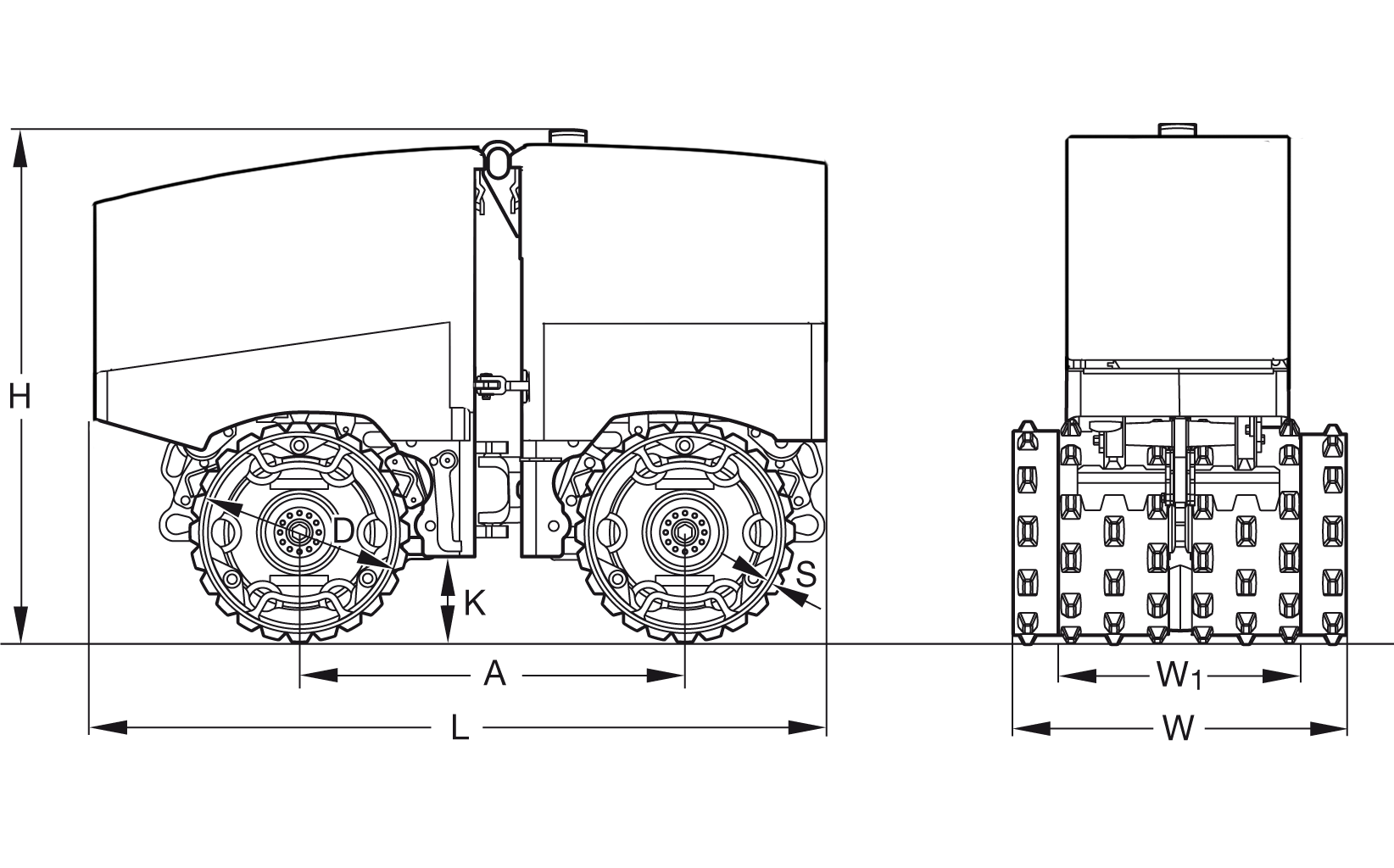

After 15 years in the BOMAG FAYAT GROUP product line, it was time to update the BMP 8500 trench roller. In addition to performance optimization, the new version of the machine should receive its own wireless remote control, which can be stored and charged in the machine, protected from the weather and theft.

In compliance with the many functional parameters, the goal was to design a trench roller that would be powerful and robust, equiped with the current design DNA, and clearly fit into the BOMAG FAYAT GROUP product portfolio.

ANALYZE

The BOMAG trench roller is a „workhorse“. Built sleek and equipped with a powerful diesel engine, it is used where it is often too dangerous for workers to handle heavy equipment, such as in trench- and sewer-constructions. If the side walls of the ditch actually collapse, the machine is excellently protected with its high-impact resistant composite material.

The basic design of the frame should remain unchanged, but the two hoods had to be completely reworked due to a larger diesel pump and the possibility of storing and charging the remote control in the machine.

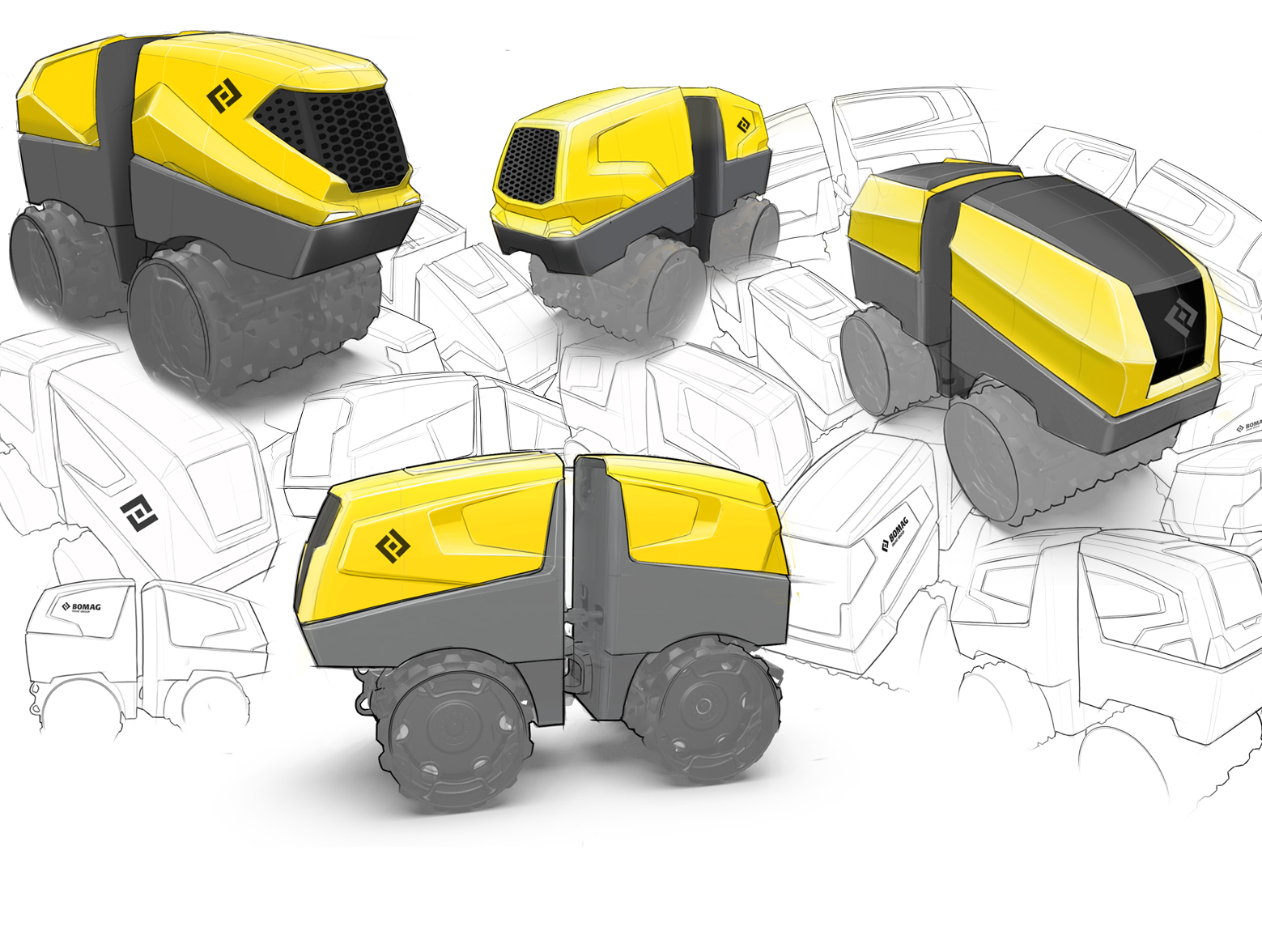

IDEATION

STEP BY STEP TOWARDS A DESIGN THAT WORKS

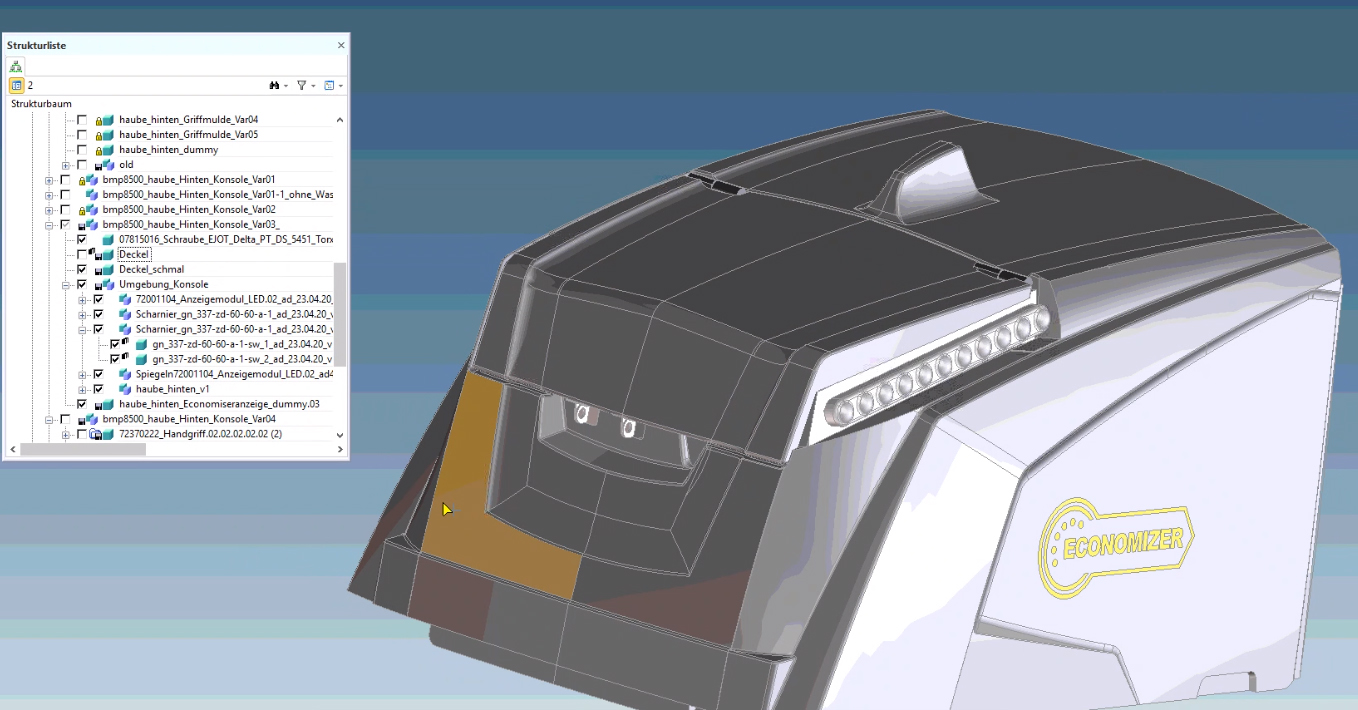

CAD MODELING

LIGHTNING

The idea of equipping the machine with worklights was also pursued. Many variants were created and evaluated for this purpose. In the end, the idea was rejected because of the costs.

DETAILING

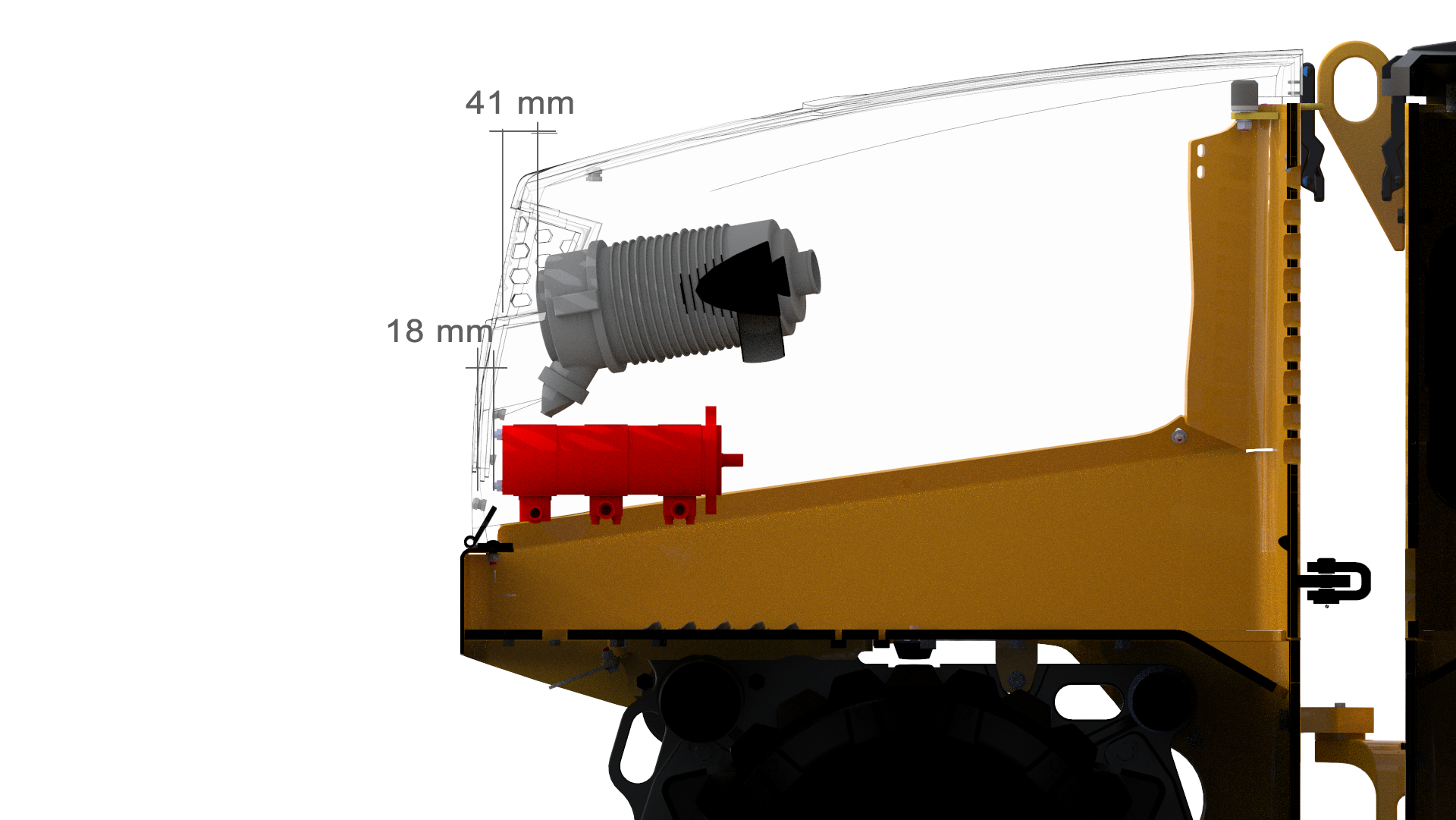

INTAKE

The design of the ventilation area for the installed diesel engine had a significant impact on the appearance of the machine. Technically, it had to be made of sheet metal and be integrate it into the hood concept. In this process, it was necessary to ensure that the engine was supplied with sufficient air for cooling.

BONNET

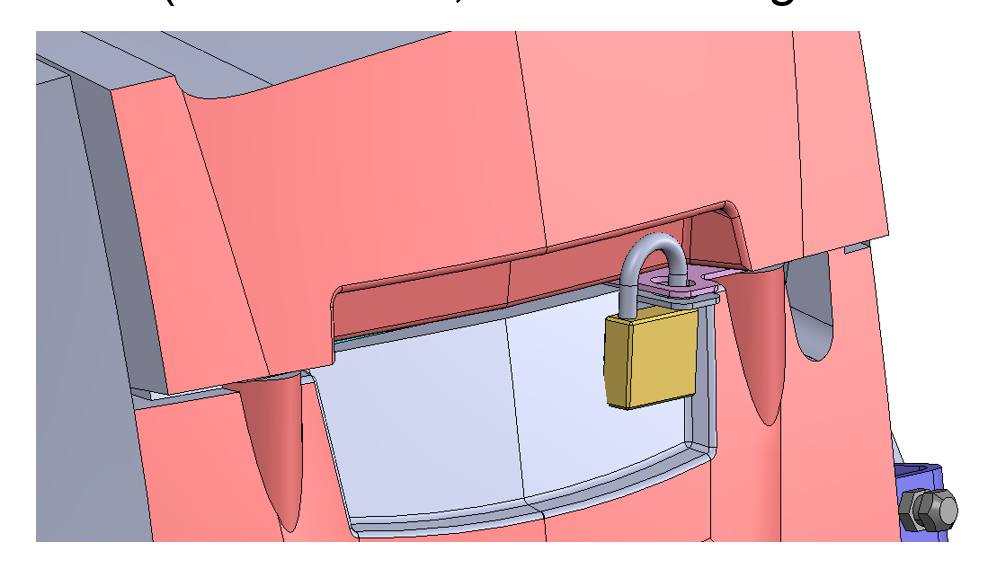

The biggest challenge was designing the remote control compartment so that the hood could be made from one piece. The lid should open 90 degrees, be water- and theftproof.

FINAL DESIGN

Finally, a machine was realized, that meets all requirements for functionality and design.

Sharp edges separate the slanted surfaces and generates a complex interplay of light and shadow. Paired with a dynamic linework, the machine achieves its modern and dynamic expression.

After more than three years of planning and construction, the BMP 8500 was finally completed in 2024 and was enthusiastically received by a large audience of experts a year later at BAUMA 2025.

Phone

(+49) 160-5189458